マッキベン型人工筋肉のレシピ 日本語ページ

Update History

- 2022/01/21: Released the recipe for artificial muscles with a 9mm diameter on this page.

- 2022/11/22: Released the recipes for artificial muscles with 7mm and 5mm diameters on GitHub. NEW Lead developers: Professor Naniwa from Osaka University’s Osuka Lab & Dr. Goto.

- 2023/01/11: The development and dissemination activities of this recipe received the “Society of Instrument and Control Engineers Kansai Branch Head Award, Technology Award.”

- 2023/06/01: Opened a question form for making artificial muscles (and others).

Abstract

This page shares the recipe for McKibben-type artificial muscles co-developed by Yoichi Masuda (Osaka University), Keisuke Naniwa (Kobe University), Daisuke Nakanishi (Matsue College of Technology), Daisuke Ura (Osaka University), and Yasuhiro Sugimoto (Osaka University). The McKibben-type artificial muscles introduced here (hereafter referred to as artificial muscles) are designed with the goal of enabling mass production solely through manual labor and with limited facilities by students who have not undergone any special training. Specifically, these artificial muscles have the following features:

- Can be manufactured in 1 to 3 minutes per unit, even by beginners

- Operable at an air pressure of 1MPa

- Easy to attach and detach

Furthermore, these artificial muscles are designed with the following concepts to achieve the above features:

- Reduction and stabilization of the manufacturing process

- Improved strength against external forces

- Simplification of the fixation method

Introduction

Recipes for artificial muscles are rarely described in detail within academic papers. As a result, individual laboratories have been developing their own unique recipes through trial and error. However, these know-hows are often not shared publicly, though there are exceptions (such as those published in references [1] and [2]).

For laboratories that want to enter the fields of biomimetic robotics or soft robotics, the development of a recipe for artificial muscles can become a barrier to entry. This page aims to improve this situation by publishing a recipe for McKibben-type artificial muscles that can be used in small to medium-sized robot research, in order to energize the fields of biomimetic robotics and soft robotics.

For those who find making artificial muscles cumbersome, or need stable and high-performance artificial muscles, the artificial muscles sold by S-muscle Company are recommended.

Conventional methods

One particularly important and challenging step in creating McKibben-type artificial muscles is sealing the ends to trap high-pressure air inside the muscle. The orthodox method involves winding wire around the ends [1]. This method requires a certain level of training to wind the wire. While using cable ties [2] is simpler, it only works under relatively low air pressures. Using strong adhesives [3,4] has the advantage of producing thin, compact muscles but demands skill from the manual laborer. Therefore, the authors have worked on developing artificial muscles that offer numerous benefits, including reduced and stabilized work processes, increased strength, and simplified attachment and detachment.

References:

- [1] Takuma, “Legged Robot Driven by Soft Pneumatic Actuators“, Journal of the Robotics Society of Japan, Vol. 37, No. 2, 2019.

- [2] “Open Soft Machines” [Online]. Available: http://opensoftmachines.com/2018/09/miniextensiblemckibben/?lang=j

- [3] “S-muscle” [Online]. Available: https://www.s-muscle.com/

- [4] “Koganei Pneumatic Artificial Muscles Pneumuscle” [Online]. Available: https://www.mirai-projects.com/pneumuscle

In terms of the work process, we eliminated the wrapping of wire and the difficult gluing steps, opting instead for a method that uses hose clamps for crimping alone.

For the improvement of strength against external forces, we designed a structure that absorbs external forces using only the crimping metal fittings and the outer braided tube. By using this crimping method, the crimping metal fittings are fixed to the outer braided tube, and the opposite side of the braided tube is fixed to another crimping fitting. Thus, even if external forces pull on both ends of the crimping fittings, the force does not transfer to the inner rubber tube or the end plugs. This prevents the main patterns of destruction in McKibben-type artificial muscles: bursting due to the plugs coming out or the collapse of the mesh as the braided tube slips off the crimping fittings.

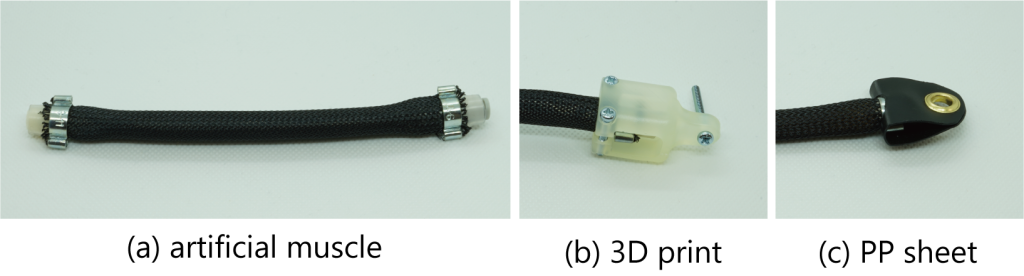

For the simplification of attachment and detachment, we took advantage of the property that part of the crimping fitting protrudes radially from the artificial muscle. This allows the crimping fittings to hook onto connecting parts (components that connect the artificial muscle to the robot’s skeleton). The diagram below illustrates this. If you have access to a high-performance light curing printer or similar equipment capable of producing sturdy connecting parts, we recommend the method in the center (b). However, if such equipment is not available, you can cut out a resin sheet with scissors or a laser, pass the artificial muscle through it, fold it, and then fix it with grommets on both sides as shown on the right (c). This method provides sufficient strength and makes detachment and attachment easy, even with screws.

Below, we will explain the specific manufacturing method.

Movie

Please start by watching the video. You will be able to understand most of it by watching the video.

Here is the experimental environment for moving the artificial muscle. Pneumatic pumps are surprisingly inexpensive.

Manufacturing Tips

- Using ABS Adhesive: Apply plenty of adhesive to the air plug. After inserting the plug into the silicone tube, roll and knead the plug and the silicone tube with your fingers to make the adhesive spread evenly over the surface of the plug.

- Crimping the Metal Fittings: When crimping the metal fittings at both ends, do so gradually to avoid biting into the sleeve or rubber. Ensure that the crimping fitting does not bite into the silicone tube or sleeve too much. Finally, use the full grip of the tool to apply maximum force for crimping.

- The Final Touch with a Lighter: The key to this design is using a lighter at the end. Melt and curl only the outer black sleeve to hook it onto the crimping fitting. If it’s not working, it’s okay to give up and instead flow instant glue between the crimped fitting and the sleeve after crimping.

Error Handling

- When It Breaks: If it breaks when force is applied or the sleeve keeps slipping off no matter what, try flowing instant glue between the fitting and the sleeve. If you don’t singe the ends of the sleeve to make them frizzy in the last step, the fibers of the sleeve may slip out from the crimping fitting.

- Air Leaks: ABS adhesive is used to fill the layer marks of the 3D printed air plug. If there’s not enough adhesive or it’s not evenly spread, air leaks can occur. The adhesive not being dry can also cause leaks, so consider leaving it for about an hour after crimping. Also, always use the specified type of straight connector (Straight KQ2H metric size KQ2H04-00A). Using a different one because it’s cheaper can lead to issues due to slight differences in diameter and might not seal properly.

Materials

Pneumatic Starter Set – A set for everything related to the pneumatic source. Having this set allows you to conduct various experiments, possibly expanding the scope of your research. The cost is around 30,000 yen. You might be able to get it for a bit over 20,000 yen if you opt for a cheaper compressor.

Materials for Pneumatic Source:

- SK-11 Air Compressor SR-L04SPT-01: 25,190 yen (all prices include tax)

- Nitto Kohki Tube Fitter Attached Hi Cupla 200 Plug 60PC: 615 yen

- PISCO Ball Valve Union BVU20-0606: 1,529 yen

- TRUSCO Polyurethane Tube TEN-6-10: 1,273 yen

- TRUSCO Polyurethane Tube TEN-4×2.5-10: 763 yen

- PISCO Reducing Union Straight PG6-4: 263 yen

McKibben type artificial muscle:

Here is a highlight of this topic. It is compatible with 4mm tubes, with an inner diameter of about 7mm and an outer diameter of about 9mm. The tools cost about 2,000 yen, and the artificial muscle costs about 1,000 yen per meter. Buying braided tubes and silicone tubes in bulk (around 10m) is cost-effective.

Materials for Artificial Muscle:

- DENKA ELECTRON Hard-to-Fray Braided Tube NFL-9: 648 yen

- MONOTARO Silicone Tube MGJG-8×10: 279 yen

- ESCO 9-11mm Hose Clamp (Two-Ear Type/10 pieces) EA463AE-11: 506 yen

- SMC Straight KQ2H Metric Size KQ2H04-00A: 318 yen

- APOLLO Hose Crimping Tool: 2,290 yen

- TAMIYA Tamiya Cement (for ABS) ITEM 87137: 278 yen (for smoothing the layer marks of 3D printed items)

- 3D Printed Items: ABS plugs link

- Can be produced with a general thermal layer 3D printer

- For preventing air leaks, an infill of 100% is ideal

- Can also be substituted with a combination of “PISCO Plug PP4” and “SMC Straight KQ2H Metric Size KQ2H04-00A”

Fixtures for Attaching Artificial Muscles This is the connecting part between the robot and the muscle.

If you can use high-strength 3D printing materials:

- Please print the CAD file (Link).

- Examples of high-strength 3D printing materials include Form3 Durable Resin, MarkTwo Carbon Filament, etc.

If you cannot use high-strength 3D printing materials:

- Materials for Simple Fixtures:

- Acrylic Sunday PP Craft Sheet PS-3 S 0.75: 692 yen

- Manufacturer Optional Double-sided Grommets (inner diameter suitable for the screws used for connection)

- Manufacturer Optional Double-sided Grommet Punch (suitable for the diameter of the grommets)

- Manufacturer Optional Punch (suitable for the diameter of the grommets)

References

Usage Permissions and Others

The content on this page was presented at the 34th Autonomous Distributed Systems Symposium. The artificial muscle manufacturing methods introduced on this page can be used without the permission of the page administrator. There is no need to provide usage licensing or credit notation.

While citing these methods in papers or manuscripts is not mandatory, doing so could help spread awareness of this recipe and contribute to the development of related fields.

We welcome comments, citations, suggestions for improvement, and advice.

Questions, Requests, and Utilization Reports

Please feel free to use this form for any questions, requests, or to report on your use of the information. Suggestions for future projects or requests are also welcome. Reporting utilization is not mandatory, but reports make the team happy.

We have opened a form for questions on making artificial muscles (among other things) for troubleshooting purposes.

Conference Presentations

Keisuke NANIWA, Yoichi MASUDA, Daisuke NAKANISHI, Daisuke URA, Yasuhiro SUGIMOTO, A Musculoskeletal Robot Tool Kit, The Proceedings of JSME annual Conference on Robotics and Mechatronics (Robomec), 2022, Volume 2022, 2022, Session ID 2A2-M08, Pages 2A2-M08-, Released on J-STAGE December 25, 2022, Online ISSN 2424-3124, https://doi.org/10.1299/jsmermd.2022.2A2-M08